The steel consumption in a country is often a reflection of its economic development and industrial growth. To boost domestic steel production, the Government introduced the National Steel Policy (NSP) 2017 on May 8, 2017, with the goal of accelerating the development of the steel industry. The policy aims to fulfil the domestic demand for steel, including high-grade automotive steel, electrical steel, special steel, and alloys for strategic purposes. By 2030-31, the policy targets a crude steel production capacity of 300 million tonnes (MT), with a production goal of 255 MT, and a significant increase in finished steel consumption per capita to 158 kg, compared to the current 97.7 kg. India's crude steel production and finished steel consumption have grown at a compound annual growth rate of 12% and 14% respectively over the last four years, which is significantly higher compared to the global growth rate of less than 1%. This growth indicates significant potential for the Indian steel sector to expand well beyond 2030, driven by rising demand in construction, automotive, defence, and infrastructure sectors. This positions India as a bright spot in the global steel market, especially in view of either stable or declining steel demand in developed nations. By focusing on increasing production capacity, improving product quality, and meeting domestic demand, the policy strives to make India a self-reliant, competitive global player in the steel industry.

About Us

Backbone of Indian Infrastructure

The Ministry of Steel oversees the development and regulation of the steel industry in India, with a vision to make India a global leader in steel production. It formulates policies, fosters innovation, and ensures sustainable sector growth. The Ministry plays a key role in setting up iron and steel production facilities, including electric arc furnaces, induction furnaces, re-rollers, flat products units, coating units, wire drawing units, and steel scrap processing. It also focuses on the development of iron ore mines in the public sector, along with other key minerals essential to the steel industry. The Ministry manages the production, distribution, pricing, and trade of iron, steel, and ferro-alloys. By promoting technological advancements and enhancing steel quality, it contributes to India’s economic growth and meets the rising demands of the steel industry. The Ministry is presently headed by a Cabinet Minister, assisted by a Minister of State and other senior officials.

IISCO STEEL PLANT, Burnpur

Green Steel Initiative

Decarbonizing the steel industry is a global challenge due to its energy-intensive processes and carbon-heavy inputs. India is focusing towards sustainability and climate change. In alignment with the announcement made by Hon’ble PM in COP26 Summit to reduce carbon intensity of India’s economy by more than 45% by 2030 and achieve net-zero by 2070, Ministry of Steel has initiated a journey towards producing low-carbon steel in a sustainable manner, implementing streamlined efforts and strategies to facilitate the sector's transition. These initiatives aim to decarbonize the steel industry by leveraging multiple technological and process-oriented solutions.

Towards this, Ministry has published a comprehensive report titled “Greening the Steel Sector in India: Roadmap and Action Plan” outlining the strategies for green transition of the steel sector. Recently, Green Steel Taxonomy for India has been notified as a foundational tool for the development of green steel market, driving investments in green technologies and thus enhancing India's role in the global industrial decarbonisation landscape

Green Steel Initiative

Raw Material Security

Raw Material Security

Raw material is a critical enabler for ensuring sustained growth in iron & steel industry. The industry faces challenges both in the short and long term in terms of raw material security. Ministry of Steel takes up related raw material issues with Ministry of Mines, Ministry of Coal, Ministry of Environment, Forest and Climate Change along with Logistic Ministries and the concerned State Governments.

There is sufficient reserve of iron ore and non-coking coal in the country to meet the current demand/consumption by domestic steel industry. However, the coking coal is imported as the supply of high-quality coal/ coking coal (low-ash coal) in the country is limited as compared to the demand which is primarily used by Integrated Steel Producers.

Steel CPSEs have been procuring coking coal from a diversified group of countries mainly Australia, United States, Indonesia, Mozambique, Russia etc. As Coking coal is a major chunk of manufacturing cost in steel production, Ministry of Steel is continuously making efforts to reduce the import bill of coking coal by diversifying the import destinations, maximize use of Pellets to reduce Coke requirement, beneficiation of iron ore to increase iron content, coking coal blend optimisation etc. Additionally, Ministry of Steel and Ministry of Coal have planned to reduce the burden of import bill of coal under the Mission Coking Coal by increasing domestic coal production from existing mines and setting up of new washeries. In order to enhance the availability of domestic coking coal to steel industries, steps have been taken which include allocation of coking coal block, auction of coking coal, MoU for coking coal linkage etc.

AI & Digitalization

The Ministry of Steel encourages the adoption of AI and digital technologies to improve efficiency, reduce costs, and enhance sustainability in the steel sector. Leading PSUs are adopting AI and digitalization to enhance operational efficiency and competitiveness, integrating innovative solutions such as drone-based mineral exploration, remote sensing, fleet management systems, simulators for HEMM operator training, drill and blast optimization, smart HEMM, real-time stockpile management, UMLMS, automated sampling, business intelligence, ICCC, CCTV surveillance, and smart metering. Additionally, they are implementing initiatives like automated zinc coating control using AI, coal blend cost optimization tools, and AI-based silicon prediction models in blast furnaces to further optimize processes, improve productivity, and enable data-driven decision-making.

AI & Digitalization

Specialty Steel

Specialty Steel

The Ministry of Steel, Government of India, is actively promoting the development of specialty steel through several strategic initiatives. A cornerstone of this effort is the Production Linked Incentive (PLI) Scheme for Specialty Steel launched on July 29, 2021. The scheme focuses on boosting domestic production of specialty steel grades, which are high-value and have applications in various sectors like defense, automobiles, and electrical appliances. This reduces reliance on imports and promotes "Atmanirbhar Bharat" (self-reliant India).

In its first phase, the scheme attracted 44 projects from 26 companies, with a committed investment of approximately ₹27,106 crore and the creation of 24 million tonnes of downstream capacity. The Ministry of Steel recently launched the second phase of the scheme, termed as PLI Scheme 1.1, on January 6, 2025, which includes relaxed norms (e.g., lower investment thresholds), carry-forward provision for excess production..

Research & Development

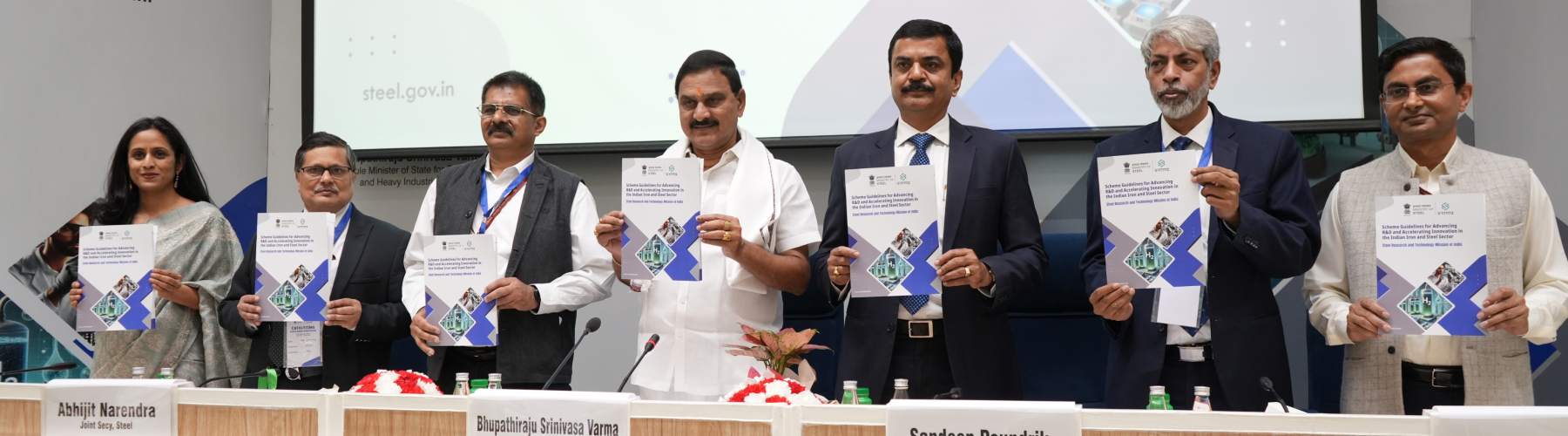

Ministry of Steel is providing financial assistance through a Government funded scheme: “Promotion of Research and Development in the steel sector” for pursuing R&D to address the technological issues faced by the sector and also indigenous development of processes/ technologies.

The thrust areas for providing financial assistance under the R&D Scheme, are development of new alternate processes & technologies to address the challenging issues faced by the Iron & Steel Sector such as climate change (green steel production, H2 based steel production, CCUS etc.), waste utilization, resource efficiency, etc.